About Van Meeuwen

Van Meeuwen specializes in lubrication and offers companies intelligent lubrication maintenance solutions, enabling them to optimize their machinery, employees, and products. We have been providing these services for almost 90 years.

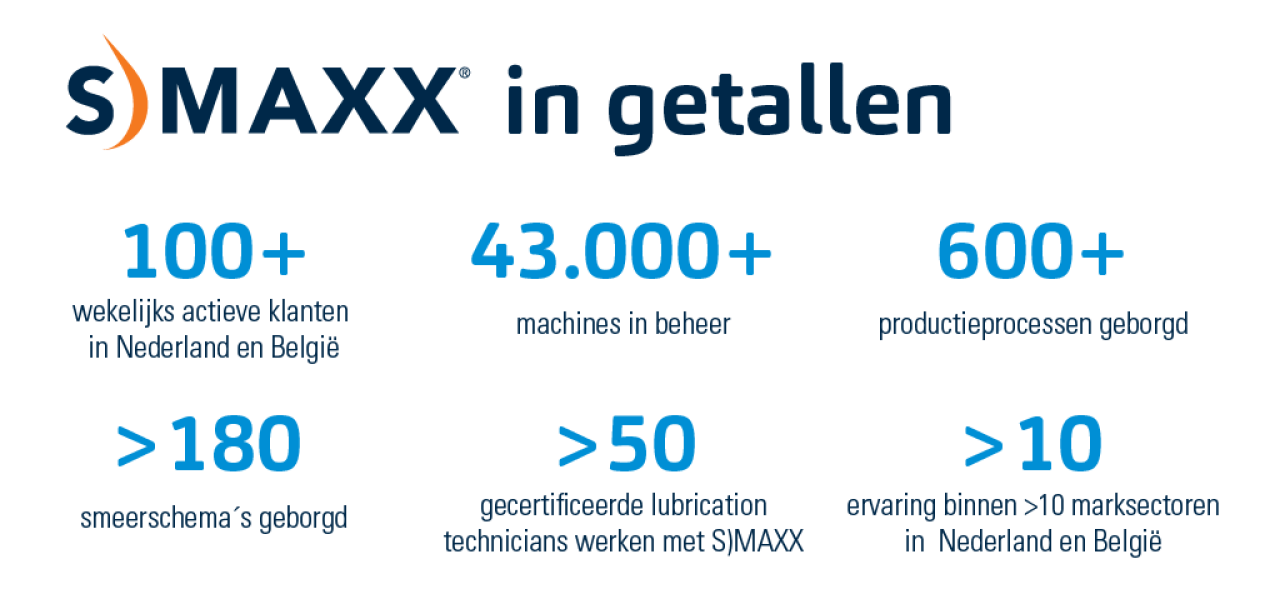

Our S)MAXX software has been digitizing lubrication maintenance processes since 2012. By offering this software as a package, we offer companies a more transparent, simplified, and dependable approach to lubrication maintenance.

Would you like to learn more about our other lubrication maintenance services?

The development of S)MAXX

Simpler, more Transparent, Smarter

Van Meeuwen has been providing lubrication services to businesses since 1990. In the past, we relied on paper-based checklists, standard walking routes, and incomplete task verification. However, since 2012, we have been digitizing these processes through an application.

Our primary goal is to ensure reliable lubrication maintenance, provide transparency, and continuously improve, manage, and monitor it more efficiently. Practical verification of lubrication tasks is the foundation of our approach.

We have been developing and managing our software with an in-house development team since 2020. This has resulted in faster software development, as our developers work closely with our experienced lubrication specialists.

By offering our software, we provide businesses with access to professional and transparent lubrication maintenance services.

Inteview: In what ways does S)MAXX assist organizations?

Step 1: From asset breakdown to lubrication plan

Placing machines can lead to an asset breakdown. "That is the basis for our lubrication plans," Minderman begins. "With machine manuals, we arrive at a theoretical lubrication schedule. Where packages like SAP, Maximo, and Ultimo have the machine at the lowest level, we look two levels deeper. The machine components are on their own layer, with all lubrication maintenance tasks underneath."

Minderman continues: "Unfortunately, it is rare that the machine manual describes the situation on the production floor exactly. In addition to position, ambient temperature, and execution, requirements such as food safety or water-repellent lubrication are also important factors. Our experts provide this improvement and thus arrive at a customized lubrication plan."

Step 2: Dynamic lubrication, registration, and updatingplans," Minderman begins. "With machine manuals, we arrive at a theoretic

For the execution of a lubrication plan, Van Meeuwen has developed its own maintenance software platform. Through an app, this so-called S)MAXX platform provides the executor with the best overview of the lubrication maintenance tasks at any time.

After execution, registration and scheduling of the task follow. Minderman: "When a task cannot be performed, the app offers the option to refuse the task, which is reported as 'task not performed'. Updating is also done with the app, where all possible changes can be requested."

Step 3: Analyzing, visualizing, and implementing "Smarter Lubrication"

Minderman explains, "Trends or deviations in the data are reasons to discuss improvement projects. Examples include moving lubrication points, improving lubrication/control frequencies, further data collection through sensors, oil sampling, and combining data from another source. Root Cause Analysis can also be supported with data from S)MAXX."

Step 4: Strategic Implementation

Finally, Minderman says, "Not every organization has maintenance at the same level. Through analysis and solutions at an appropriate level, Van Meeuwen assists with the development of lubrication maintenance and thus with Smarter Lubrication using the S)MAXX platform!"